2004

About

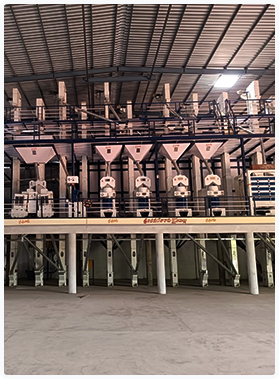

Leaders in Modern Grain Processing Machinery

RICETECH Machinery is a renowned manufacturer, supplier, and exporter of cutting-edge modern grain processing machinery. With a comprehensive portfolio of innovative products, we cater to the evolving needs of paddy and pulse processing industries.

Milestones

Garnering the trust of over 5000+ customers in India.

Mission

Empowering Millers, Enhancing Food Security

Vision

Elevating Food Processing through Innovation

Quality Assurance

As an ISO 9001:2015 certified company, we adhere to the highest quality manufacturing standards, compliant with European norms. Our products have obtained the esteemed CE Marking, underscoring our commitment to excellence.