2004

About

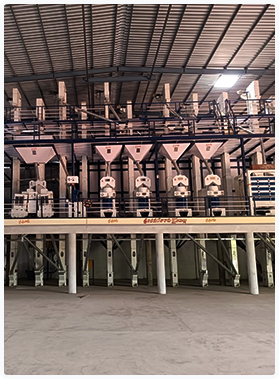

Leaders in Modern Grain Processing Machinery

RICETECH Machinery is a renowned manufacturer, supplier, and exporter of cutting-edge modern grain processing machinery. With a comprehensive portfolio of innovative products, we cater to the evolving needs of paddy and pulse processing industries.

Our Legacy

Since our inception in 2004, we've been committed to designing and manufacturing world-class machinery that minimizes processing losses. Our team of expert technocrats has successfully developed machinery that has earned us appreciation from our esteemed customers.

Milestones

With over 21 years of experience, RICETECH has established itself as a trusted brand, garnering the trust of over 5000+ customers in India. Our export footprint extends to neighbouring countries, including Nepal, Bangladesh, Sri Lanka, Nigeria and Myanmar.

Quality Assurance

As an ISO 9001:2015 certified company, we adhere to the highest quality manufacturing standards, compliant with European norms. Our products have obtained the esteemed CE Marking, underscoring our commitment to excellence.